Natural honey packaging is very challenging, and it is imperative for honey business to have a good honey filling machine to ensure producing efficiency and quality. Due to its size, honey presents unique filling challenges that require specific features in filling machinery. These are the main points at which a honey filling machine scores well and it uses to work smoothly creating product in the same consistency.

Viscosity contamination handling (e.g. specialized handling)

Any honey filler is intended to deal with the thickness of honey, but a reliable honey filling gear is supposed to deal with the higher thickness. Hot tank (heated tanks and nozzles) machines keep honey at a consistent temperature that is just right for flow. This comes in handy as the sugar inhibits the honey to crystallize thereby ensuring that the honey flows easily through the equipment. More advanced devices deliver accurate temperature controls that are customizable according to the respective honey types which improves its versatility and efficiency.

High Accuracy Filling Systems

Honey requires precise filling with no errors. Most high quality machines are accurate within ±1% meaning they willmeasure out the perfect amount of product into each container and thereforethey will comply with the legal weight regulations and the inside of the jar orcylinder will be packed which means customers are getting what theyexpect. Servo-driven or volumetric piston fillers are usually employed in such cases, as they are accurate and provide consistent and repeatable dosing.

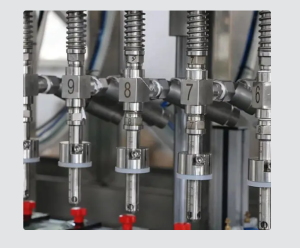

Robust Construction Materials

A honey filling machine, like any other, is only as reliable as the materials that it is constructed of. This is the preferred material because of its corrosion resistance and easy clean nature. Machinery constructed from quality stainless steel are built to last and are far less prone to rusting, which could cause honey contamination and result in production downtime, therefore calling for costly maintenance.

Easy Maintenance And Clean Up

A sticky substance like honey has to be handled by a machine that is easy to clean and maintain. Sanitary features of models, such as those with smooth weld seams, quick release fittings and minimized dead space, allow for easy and full cleaning and sanitizing of the surface. The machine is designed to minimize downtime, lower maintenance costs, and maximize the operational life of the machine with easy access to parts and simple assembly for rapid maintenance.

Flexible to the demands of Production

Reliable Honey Filling MachineComes With Production Flexibility Being able to produce on a large scale yet maintain that specific texture, taste, and overall quality all the way through is the true power of a reliable honey filling machine. Select for machines that can change over quickly without much downtime to fill different sizes and shapes of containers. This flexibility makes the machine a viable asset on several product lines which helps maximising the investment.

AVR (Automated Volume Regulator)Ease of the control and the monitoring systems

Reliable machinery is characterized by advanced control systems. A good quality honey filling machine will come with automatic control panels, programmable logic controllers (PLCs) and touch screen interfaces to make the job easy as always. By providing exact control on filling characteristics, the systems can incorporate a range of diagnostics and monitoring options to aid in predicting maintenance requirements and avoiding breakdowns.

Improving Your Productivity

To summarize we can say it is essential for a business when it comes to honey packaging machines to invest in the proper, reliable machine. Through the use of design options for the viscometer of VFD control of the proportions and the control systems of ball valve and both integrations, a complex and repeatable design is possible to achieve inherently efficient operations while enhancing quality and product conformity. These functions are so important for successful packaging as they preserve the quality of the honey, as well as increasing productivity and reducing operational costs.